Prepared for the worst case scenario

More safety for mining machines due to the multi-sound module

The larger the better. This could be the motto when the topic is open cast mining and the machines used there. Yet the fact that the machines, which are several storeys high, function safely and reliably thanks to the use of electronics. Miunske also has a small but safety-related share of the mining of ores.

If one asks Florian Schwanse, it has never occurred to date. Nonetheless, his customer wanted to be sure. Because the worst case looks like this: A chisel of a mobile ore crusher breaks off unnoticed, is loaded and lands in the crusher. The consequence is expensive repairs and the mining comes to a standstill. To ensure this does not happen, the discharging belt is monitored and the operator is signalled via a display that something is wrong. However, due to the space conditions, the display can only be positioned behind the driver. „If you want to notify the driver that there is a problem, because a metal part has passed along his belt, it is difficult if they can’t see the display“, explained Schwanse. The engineer is a developer at Indurad GmbH – a company that is specialised in the development of hardware, software and the engineering of mining and bulk material handling processes. Projects with extremely short cycles, from the idea to delivery, are nothing unusual at Indurad. Therefore a solution had to be found quickly.

Schwanse and his co-workers became aware of miunske by searching the internet: „We were looking for a sound module, which can be activated via CANbus.“ Two weeks later the delivery from Großpostwitz arrived in Aachen. „We then downloaded the miunske-toolchain software before installing the solution. From then, everything was more or less self-explanatory“, said Schwanse. „We also used a CAN sniffer to view which data are sent and received. We also clarified technical details once again with miunske, and then we could install the Multi-Sound-Module.“ However, Indurad does not use the extensive technical options. In the current version, the signal produced by the metal detector is merely converted into a beep. This acoustic warning signal is then sounding until the machine operator turns around and acknowledges the signal by pressing the reset button. „It’s like driving a Porsche at a snail’s pace“, explained Florian Schwanse.

The fact that the operating company required the equipment with a Multi-Sound-Module, has a simple albeit unsettling reason. While strict maintenance intervals and their precise implementation are common practice in Germany, this cannot be 100 % ensured in developing countries. „If a chisel should break off, there is a good chance that there are no negative consequences. Because in the best case, the operator draws the dumper driver’s attention to the fact that they have loaded a metal part. This load is then discarded and is not tipped into the crusher.” Three ore crushers have currently been equipped with the Multi-Sound-Module, which are used in the same mine. It is therefore feasible that older machines will also be retrofitted. But in future projects, Florian Schwanse will now contact miunske directly. Because the Multi-Sound-Module offers very many more options than sending a beep. „For example, we could image voice control for the human-machine interaction. But the space for installation is very limited, including in future projects.“ Schwanse summarised. Because although the mining machines hardly show it on the outside, here too the rule is: the smaller the better.

Interest in more Information?

Our online-catalogue offers a wide range of products and customized solutions.

Find here for what you need!

We configure your Topcon control panel according to your specific project requirements.

Ask your product consultant for more information.

We configure your MTA instrument according to your specific project requirements.

Ask your product consultant for more information.

Information:

Customer:

Product:

Category:

Follow us on:

additional refernces

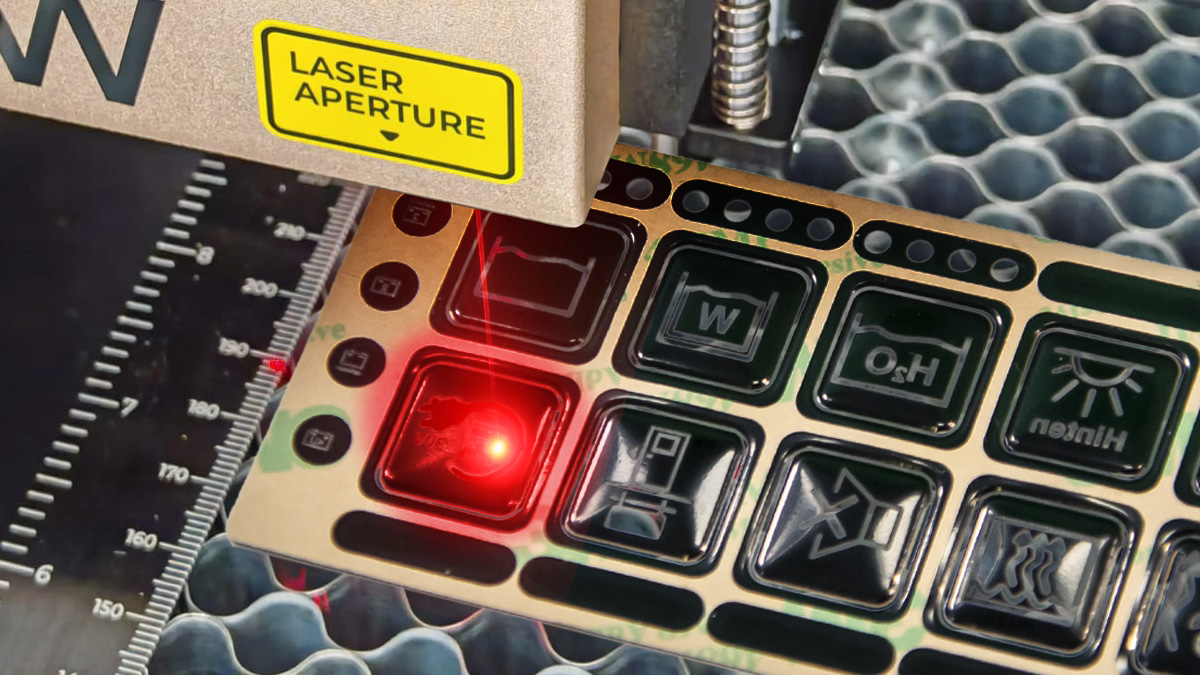

pilot control panel 9.18 with self-lasered operating foil

The pilot control unit 9.18 can meet the high demands of the automotive industry in terms of design and flexibility.

TOPCON-operating devices

miunske® integrates Topcon systems into commercial vehicles according to customer requirements for precise machine control.

pilot 4.0D display for winter service

With the pilot operating unit 4.0D, miunske offers a high-contrast display for gritting vehicles