TOPCON-operating devices

CUSTOMIZED CONTROL WITH OPUS A6

Initial situation:

Rhomberg Sersa RailTec GmbH is one of the leading international companies in the rail technology sector and consistently pursues the goal of continuously optimizing rail infrastructure through innovative concepts, first-class solutions and the use of state-of-the-art technologies. The company is also a reliable partner for the maintenance and modernization of railway construction machines, including all phases of the maintenance process and retrofit solutions.

A central focus is on the maintenance of rail vehicles, where the challenge is often to replace obsolete or no longer available components with modern operating elements without impairing the required control functions.

Task definition:

Modernization of the display technology was planned for a tamping machine used in rail construction to compact the ballast under railway sleepers. Old analogue displays should be replaced by a multifunctional display that enables central visualization of all relevant parameters. The aim was to combine the information previously shown on several individual displays, such as hydraulic pressures, temperature, filter contamination, speed, voltage, charge control, fuel level and operating hours, on a single display.

There was also a desire to integrate camera monitoring in order to monitor relevant work areas in real time and ensure safety in the machine environment.

The path to a solution

It quickly became clear that the large number of different parameters needed to be optimally combined on a central display. The project team at Rhomberg Sersa RailTec GmbH in Spremberg therefore searched for a programmable display for use in the vehicle, which also has camera inputs, and found what they were looking for on the miunske website. As a partner and system integrator of Topcon, miunske was ideally suited for a project request of this kind.

Another advantage was the regional proximity, which enabled a quick communication. A meeting was subsequently held on site with the project development colleagues from miunske, during that the various options and feasibilities were discussed in detail.

miunske then developed and programmed a layout design for the multifunctional display. The integration and commissioning of the OPUS A6 Eco Basic Plus from Topcon in conjunction with a miunske CAN module I/O5 and a CAN Gateway was carried out directly on site by the developers from Rhomberg Sersa in close cooperation with the project developers from miunske.

The Rhomberg Sersa RailTec team particularly appreciated miunske’s solution-oriented approach and willingness to share technical expertise, which contributed to the successful and efficient implementation of the project.

Added value for Rhomberg Sersa RailTec GmbH and the machine user

The use of the multifunctional display OPUS A6 made it possible to implement a modern, compact and ergonomically optimized control panel in the railway construction machine’s control station. The integration of several functions in a central display unit led to a significant reduction in the number of individual components required. This minimizes potential failure risks and at the same time reduces maintenance and service costs for the end user – a clear added value for both Rhomberg Sersa and the operators of the machines.

Information:

Customer:

Rhomberg Sersa RailTec GmbH

Product:

Category:

Follow us on:

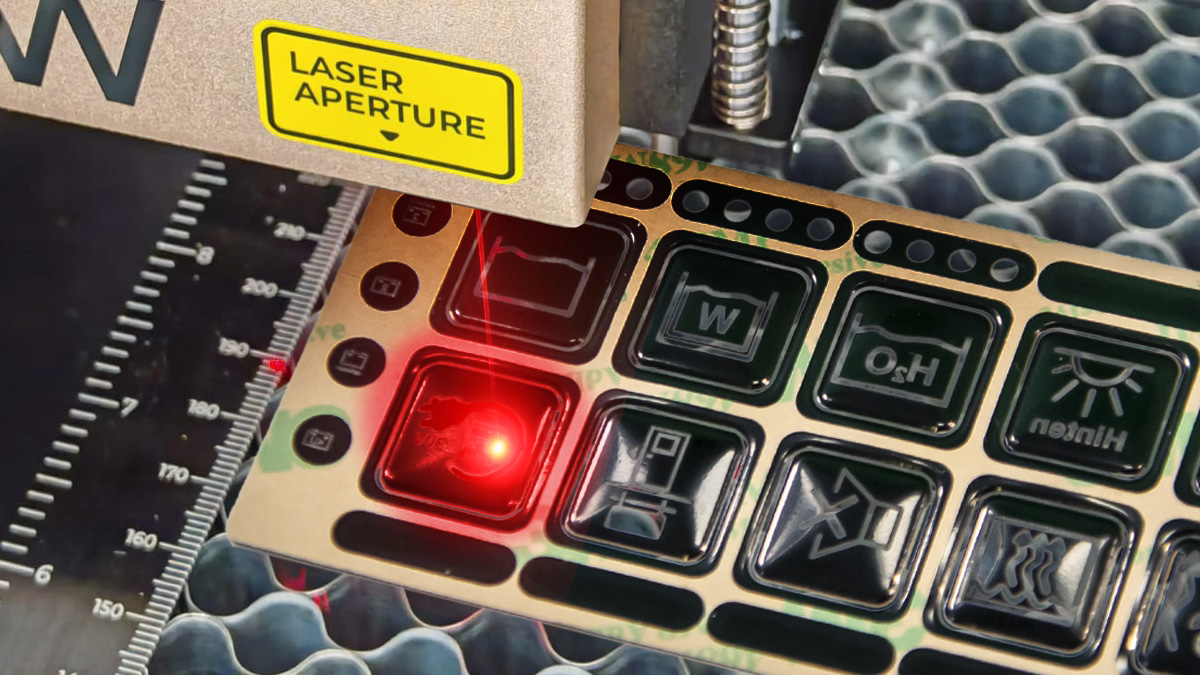

pilot control panel 9.18 with self-lasered operating foil

The pilot control unit 9.18 can meet the high demands of the automotive industry in terms of design and flexibility.

TOPCON-operating devices

miunske® integrates Topcon systems into commercial vehicles according to customer requirements for precise machine control.

pilot 4.0D display for winter service

With the pilot operating unit 4.0D, miunske offers a high-contrast display for gritting vehicles

Information

Kunde:

RSP GmbH & Co. KGProdukt:

Zentralelektrik im GehäuseCategory:

Date:

July 10, 2025