We develop what moves. Electronics for commercial and special-purpose vehicles.

Solutions

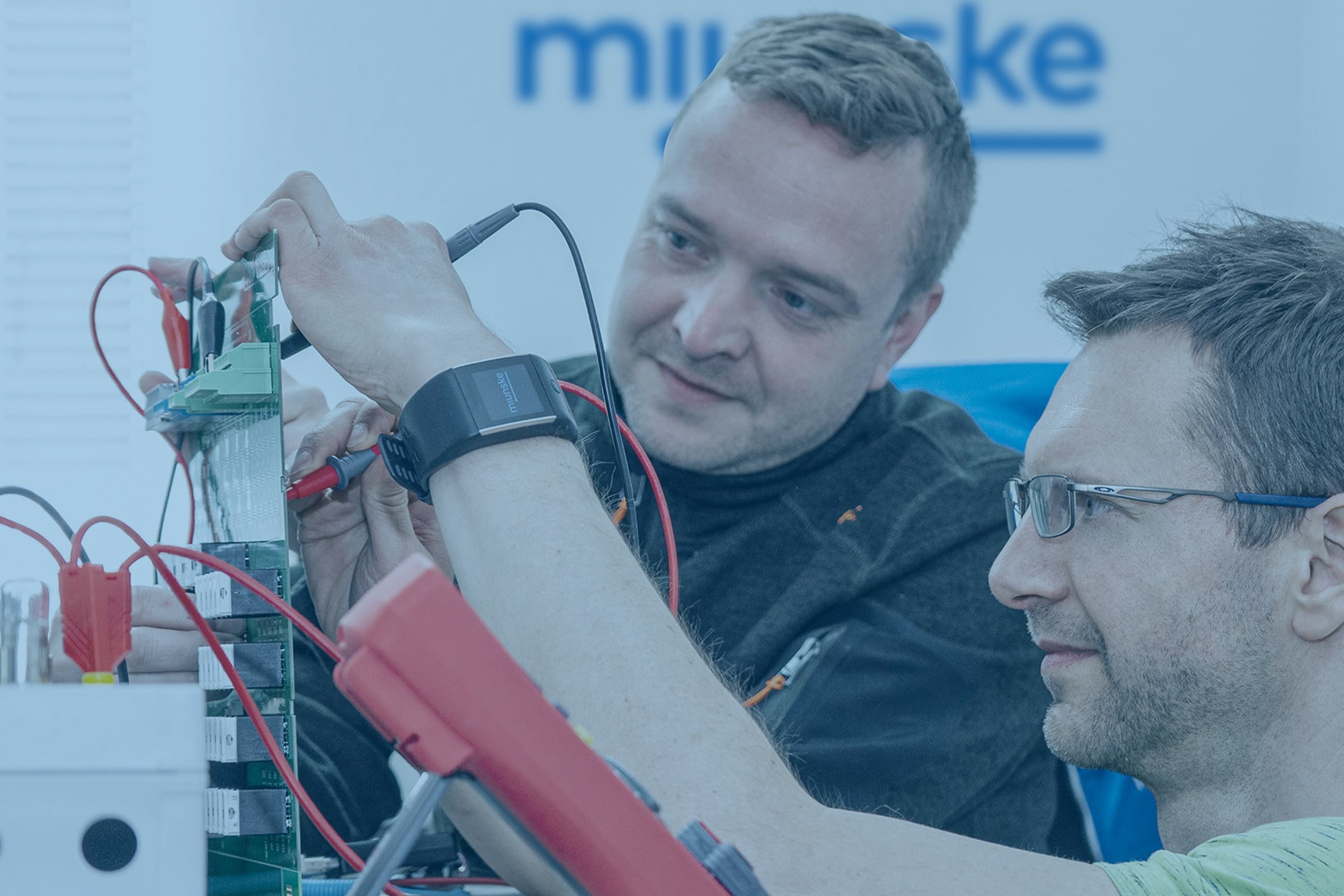

DEVELOPMENT SERVICES

Technical Consulting

We develop vehicle electronics with vision - precisely tailored to your individual needs.

Hardware Development

In addition to perfect function, our goal is to ensure the most efficient subsequent production of your electronics.

Software Development

Our miunske-toolchain offers a wide range of standard software solutions for programming and parameterizing our products.

Design and Prototyping

Whether a metal enclosure or a plastic component, we design and validate mechanical components for your requirements.

Design

Our development engineers and PCB specialists plan and develop PCB designs - precisely tailored to your needs.

Quality Assurance

We place the highest value on the quality of our components. Comprehensive quality assurance is carried out at every stage of production.

Technical support

Development tools from miunske are always state-of-the-art, because they accompany our engineers in their daily work on electronics solutions for the commercial vehicles of tomorrow.

developer team

miunske solution

Our goal is to play a decisive role in shaping the mobility of the future: to lead the way, overcome boundaries and shape innovative electronic solutions and products from ideas - for the success of our customers - and of our parent company, miunske GmbH. This claim is underlined by our name: MIUNSKE SOLUTION. It stands for engineers, innovators and inventors who are always working on the best solution. Our products provide answers to the mobility questions of the future: from the first spark of an idea to the developed electronic component ready for series production.

„MIUNSKE SOLUTION thinks in solutions - down to the smallest detail. Because even a small idea can have the power to revolutionise the whole world of mobility."

Sebastian Müller, Development Manager