Fulfilling customer requests directly at the vehicle handover

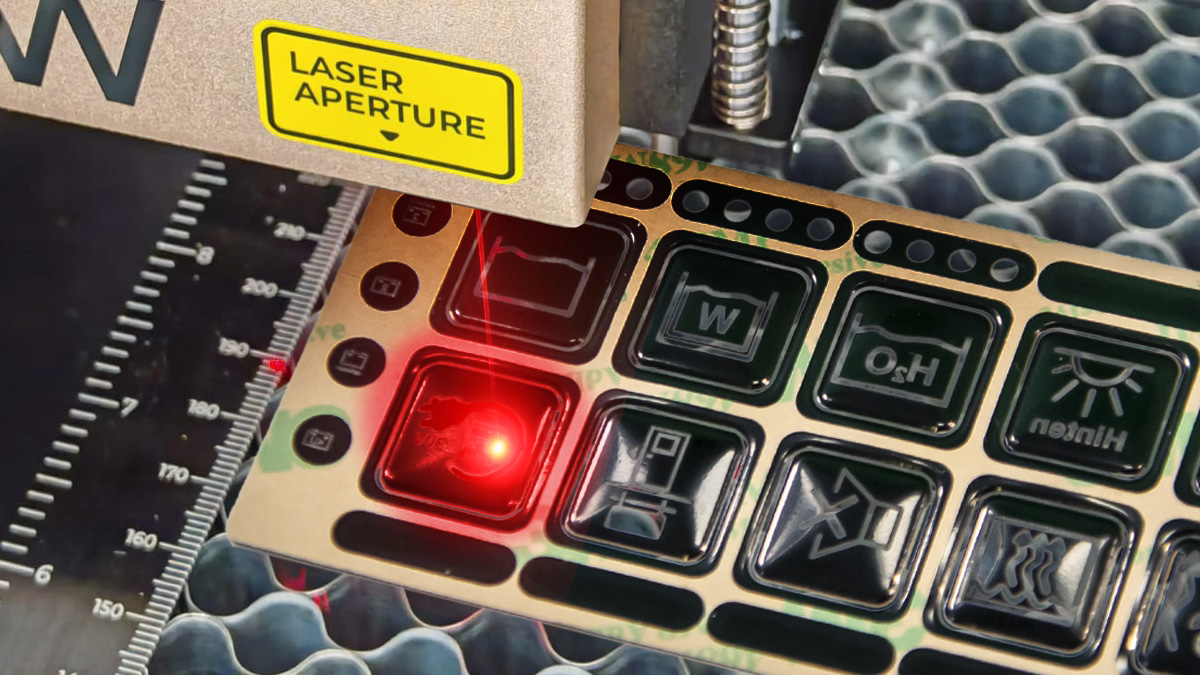

pilot 9.18 WITH SELF-LASERED OPERATING FOIL

Initial situation:

With its market promise of “Definitely the best solution,” the WELP Group stands out for its development and manufacture of certified special protection vehicles and solutions. The focus lies on the wishes, requirements, and protection of emergency services, NGOs, and even high-ranking personalities.

Task definition:

In order to meet these high standards, the developers at WELP Group opted for the pilot control panel series from miunske. Based on several years of experience working together, pilot began to be used as a control unit for additional functions in the development of customer-specific vehicle prototypes.

The decisive factors were the time aspect, the high degree of flexibility, and the high-quality design.

Until now, additional vehicle functions and connections have been implemented using complex relay circuits, which require a large amount of cabling.

During the relatively long development periods of one and a half to two and a half years, both customer requirements and technical specifications change. That is why the WELP Group’s development team considers the flexibility offered by the software-based designoptions of the pilot control panel as a major advantage.

The path to a solution

The different sizes of the basic types in the pilot control panel series allow the control functions required to be perfectly matched to the vehicle’s basic equipment or full equipment. In addition, there is the equipment-dependent adjustment of the key assignment as well as AND/OR links between functions or the implementation of variants for right-hand or left-hand drive vehicles.

Hidden functions that can be accessed by the length of the key pressure can also be implemented.

To control additional systems, such as a special signaling system, it was possible to integrate a second control unit for a separate tone sequence amplifier via an I/O module in conjunction with the CANopen standard. miunske® coordinated the programming of the control functions directly with the amplifier manufacturer, thus simplifying the integration process. An additional advantage here was the reduction in cabling costs.

Added value for the WELP Group and the end user

“It is particularly important to us to be able to respond quickly to changes, whether in prototype construction or in the delivery process. The laser engraving of the control foils and the in-house finalization of the pilot control panels at Indikar, part of the WELP Group, leave nothing to be desired and contribute to a high level of customer satisfaction.”

René Davideit, Project management and planning WELP Group – IndiKar.

Information:

Customer:

IndiKar Individual Karosseriebau GmbH

Follow WELP Group on:

Product:

Category:

Follow miunske on:

pilot control panel 9.18 with self-lasered operating foil

The pilot control unit 9.18 can meet the high demands of the automotive industry in terms of design and flexibility.

TOPCON-operating devices

miunske® integrates Topcon systems into commercial vehicles according to customer requirements for precise machine control.

pilot 4.0D display for winter service

With the pilot operating unit 4.0D, miunske offers a high-contrast display for gritting vehicles

Information

Kunde:

RSP GmbH & Co. KGProdukt:

Zentralelektrik im GehäuseCategory:

Date:

November 26, 2025