Safely through Switzerland

10 control systems for 10 different vehicles

In 1927, Karl Rusterholz laid the cornerstone of a family business, which is today one of the most modern and innovative bodywork companies in Switzerland. The company, located around 30km to the southeast of Zurich, has always carried out accident repairs on vehicles. However, Carroserie Rusterholz AG has made a particular name for itself with the production of new fire service vehicles, police and special bodies and small series vehicles for municipalities.

If you speak to Stefan Hauser about the project undertaken with miunske, he answers with expected Swiss aplomb. Even though the project manager has every reason to burst with pride. Yet one step after the other. As a specialist for custom-built products, Carrosserie Rusterholz AG received an order to retrofitten Volkswagen T6 vehicles for use as prisoner transporters. In addition to all the security aspects, a controlled air-conditioning system and camera surveillance were obligatory. An option for several vehicles to be equipped with a special signal system was also to be provided.

From trade fair visits, Hauser already knew that miunske fulfilled many of the requirements set with its portfolio. Here he met the Großpostwitz company and made his first contacts. In 2016, a visit of a distribution partner of miunske at Carrosserie Rusterholz AG followed. One of the products presented during this visit was a CAN keypad. „ We have been building prisoner transporters for around 10 years. Initially we had toggle switches and separate control units for the air conditioning system,” explained Hauser. “However, that was fairly expensive and time-consuming, as we hand-wired everything. The prewiring alone took four to five hours. The wish then arose to find a simpler way, not only for the installation but also for the operation.”

A problem that is very familiar for miunske. After all, the cost and effort required for conventional wiring often bears no relation to the different requirements. With CANbus systems, not only space can be saved and hard-wiring can be reduced, but also individual solutions can be realised. This also convinced the decision-makers at Rusterholz. „This also convinced the decision-makers at Rusterholz. “At the beginning we were still a bit sceptical about how such a change would be received. Initially we only had a sample keypad, without programming or corresponding module,“ Hauser remembered. “I showed it to my bosses and they were already enthusiastic.”

This enthusiasm triggered a rethink of solutions used to date. However, the CAN keypad is only one of several miunske products, which are used in the current project. Stefan Hauser: “We used CAN keypads for the first time in 2016. In the following year we had in-house training given by miunske, in which an employee presented the touchscreen to us. This led to the idea with the prisoner transporter.“ It was defined, partly with layouts and circuit diagrams for connection of the police technology. The objective was to obtain design certainty as early as possible. Because Rusterholz not only retrofits Volkswagen T6 transporters, but also Mercedes Vito or Sprinter vehicles and Opel Vivaro vehicles in numerous trim or equipment variations, depending on the customer. „We do not need ten different controls for 10 different vehicles. The solution must suit all variations. Including the connection of the police technology such as radio system, tracking systems, flashing blue lights,“ explained Hauser.

All power parameters are controlled by especially designed central electrics. They are interpreted and implemented by a standard I/O module. These components also forced more than a miunute to rethink from the Swiss. „We save lots of wiring work, as we receive everything preassembled. We used to have to invest hours of work, now it’s just plugging in and everything works. Miunske programs the modules for us.”

Despite the requirements specification, several discussions were necessary before everything functioned as we wanted. Because „it is always difficult to truly think of everything and to describe it in writing precisely like you imagine it. Now and again ideas about what else could be possible also arise retrospectively“, explained Stefan Hauser.

And although the Swiss are reputed to act unhurriedly, the project did not progress any slower than elsewhere. The prototype was delivered in October 2017 and, despite minor change and adjustment requests, Rusterholz was able to access the series model in December. The project is now completely developed, the products are installed and function reliably. In addition to the CAN keypad, an OPUS A3 Eco display is also used for operation and display.

With the retrofitting of the prisoner transporter, Carrosserie Rusterholz AG once again showed that there are good reasons why it is one of the most modern and innovative bodywork companies in Switzerland. Yet instead of resting on their laurels, Stefan Hauser already has the next project in focus. Because toggle switches continue to be used in large vehicle such as trucks or pump water tankers. „We naturally also want to change that. However, this again needs both time and money.“ It goes without saying that he can rely on support from miunske. However, he has not named a specific timetable. “But due to the good experience we will tackle this when time allows.”

Here you can find out more about the portfolio of Carosserie Rusterholz AG

Interest in more Information?

Our online-catalogue offers a wide range of products and customized solutions.

Find here for what you need!

We configure your Topcon control panel according to your specific project requirements.

Ask your product consultant for more information.

We configure your MTA instrument according to your specific project requirements.

Ask your product consultant for more information.

Information:

Customer:

Product:

Category:

Follow us on:

additional references

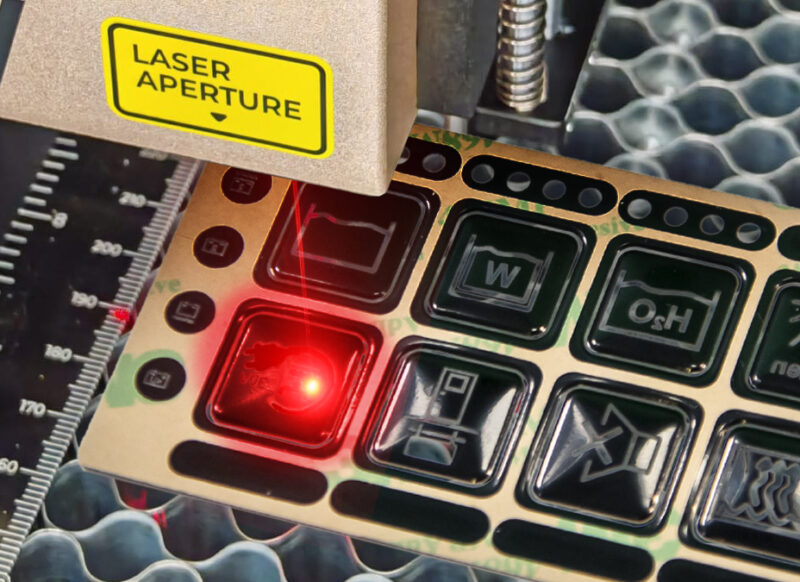

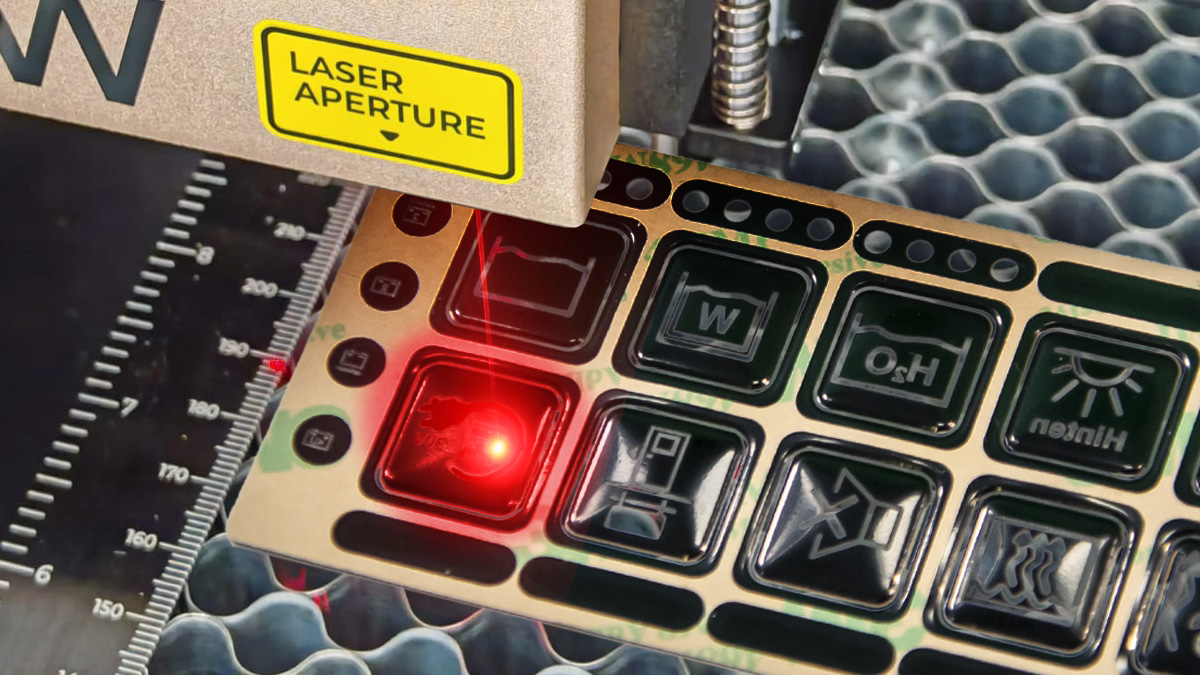

pilot control panel 9.18 with self-lasered operating foil

The pilot control unit 9.18 can meet the high demands of the automotive industry in terms of design and flexibility.

TOPCON-operating devices

miunske® integrates Topcon systems into commercial vehicles according to customer requirements for precise machine control.

pilot 4.0D display for winter service

With the pilot operating unit 4.0D, miunske offers a high-contrast display for gritting vehicles