MORE EFFICIENT SOLUTION FOR ENERGY DISTRIBUTION

LESS EFFORT FOR WIRING AND SERVICING

Initial situation:

RSP GmbH was in the development and planning phase of a new suction excavator that was to be equipped with a decentralized electrical architecture. In the previous model, the control system was installed centrally in one place, which required a lot of cabling. A terminal box was previously used to separate the cabling when dismantling mechanical components.

Task definition:

The aim was to create an efficient solution for power distribution in the suction excavator that would optimize production and the service process. RSP decided to develop an individual solution that was precisely tailored to the company’s requirements. The key requirements included

-

Suitable for mobile construction machinery, temperature range from -20°C to 85°C

-

No wiring inside the housing, as was previously the case in the terminal box, plug connections that lead through the housing to the outside.

-

A robust metal housing that is accessible for diagnostic purposes and meets the requirements in terms of space and IP protection class (IP67).

-

Use of I/O modules to implement the decentralized electrical architecture and increase diagnostic capability.

-

Expandable to be equipped for future customer requirements.

-

Version as CANopen device

The path to a solution

The development process comprised the following steps:

-

Planning the inputs and outputs and recording all the requirements for the component.

-

Analysis of sample projects on the miunske website and visit to miunske to clarify basic questions. A basic concept was then created.

-

Creation of the functional specification based on the RSP specifications.

-

Development of the circuit board including housing solution, testing and revision in close cooperation between the project developers on both sides, followed by the start of series production.

-

Implementation of the circuit board in the vehicle, including an adapted hardware architecture and standardized cable harnesses.

-

Development of customized software to expand the diagnostic options using I/O modules.

The circuit board is installed in the upper area of the suction excavator. It controls the entire electrical system of the material container cover and is an important component of the new electrical architecture, which consists of a total of 3 circuit boards.

Added value for the customer:

The new central electrical board offers a number of advantages:

-

Compact design: Numerous functions are implemented in the smallest of spaces, including the control of outputs, the reading of inputs and potential distribution. Plug connectors on the circuit board ensure greater ease of installation.

-

Standardization and flexibility: The logic is controlled by software, eliminating the need for individual wiring for each vehicle. This increases flexibility and enables standardization of the vehicle architecture.

-

Improved diagnostic options: LEDs indicate the signal status directly on the circuit board. The IO modules also enable intelligent diagnostics, such as the detection of cable breaks, short circuits and the measurement of currents.

-

Quick installation and easy maintenance: The entire central electrical system can be installed quickly and replaced easily during servicing.

-

Scalability: The circuit board can be manufactured by machine, resulting in cost savings and eliminating the need for time-consuming manual work.

-

Expandability thanks to plug-in I/O modules: These modules are only plugged into the board when required, which offers additional flexibility and further reduces costs.

O-Ton - RSP GmbH & Co. KG:

"Overall, the new central electrical solution helps to minimize cabling work, shorten assembly times and improve diagnostic and maintenance processes. It is a key component of the new, efficient and flexible electrical architecture of our new generation of suction excavators. "

Franz Schleicher, Teamleiter Steuerungstechnik RSP

Information:

Customer:

RSP GmbH & Co. KG

Product:

Central electrical board in a housing

Follow us on:

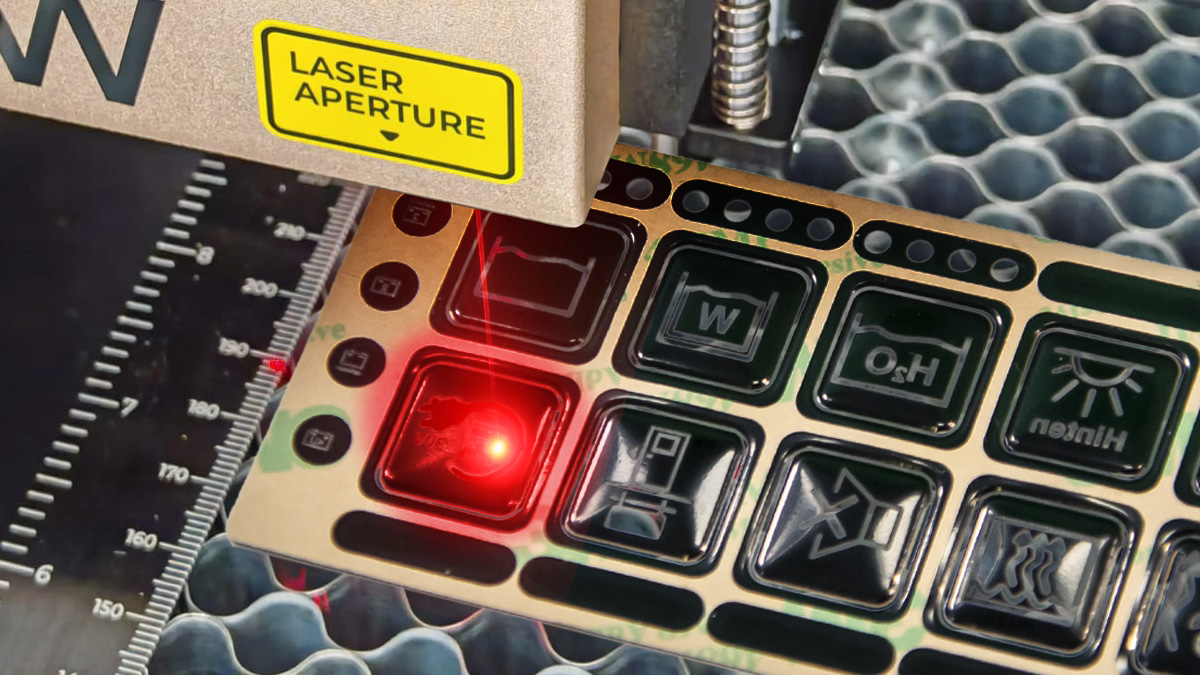

pilot control panel 9.18 with self-lasered operating foil

The pilot control unit 9.18 can meet the high demands of the automotive industry in terms of design and flexibility.

TOPCON-operating devices

miunske® integrates Topcon systems into commercial vehicles according to customer requirements for precise machine control.

pilot 4.0D display for winter service

With the pilot operating unit 4.0D, miunske offers a high-contrast display for gritting vehicles