CAN-Bus Control Panels for brilliant vehicle operation and monitoring

Operating and displaying in challenging environments

In modern commercial vehicles—from municipal vehicles to agricultural and construction machinery—well-designed control solutions are essential. CAN bus operating devices form the core of a safe, ergonomic, and functionally coordinated human-machine interface. They must not only withstand extreme environmental conditions both inside and outside the vehicle but also be adaptable to the specific requirements of different vehicle types.

miunske’s CAN switching and display units provide drivers and operators with the safety they need in their work environment. The second-generation of CAN operating devices meet the highest standards of user comfort, visual and tactile feedback, and design. miunske CAN keyboards set the standard in modern commercial vehicles.

Why they are now indispensable in any forward-looking vehicle architecture, and how configurable control units—through combinability, programmable functionality, and user-oriented design—contribute to increased efficiency and operational safety, will be discussed in the following sections.

Variants of modern CAN Bus Operating Devices

Custom-made diversity

miunske’s CAN Bus Operating Devices are available with 4, 6, or 12 control fields, which can be defined as displays, switches, push buttons, or pushers. The illumination of the fields is provided by multicolor LEDs. Additionally, each field can be equipped with vertical or horizontal bar graph display elements. Their color is determined hardware-wise by selecting unicolor LEDs. In terms of length and width, the CAN keyboards are designed to match the dimensions of standard frames. This allows them to fit easily into existing cutouts, both vertically and horizontally.

The technology behind the CAN Switching and Operating Devices

keys parameterizable in different switching states, or or completely controllable via CAN command (color, brightness, flashing)

absolute color fidelity during dimming even at the

lowest brightness settingsBar graph-LEDs assignable to 60 different positions and individually selectable colours (red, green, yellow, white, blue, orange)

connection of external encoders for operating Can-based function parameters possible

two digital Inputs to control the location lighting, the idle bus or as digital input

flashing frequency in two steps freely parametrizable with customizable flashing harmony (range: 0.2 Hz – 50 Hz)

CAN speeds of 20 kbit/s up to 1 Mbit/s, adaptable to existing CAN systems

CAN messages bit-by-bit freely configurable in a graphical symbol editor to illustrate the entire network communication

build your own graphical user interface for your device within minutes using the handy FlexGUI interface, freely delivered as part of the miunske-toolchain

use internal flash memory for your own purposes, write- readable by CAN, e.g. for redundant data storage or machine parameters

Cyclic sending of a freely configurable, fixed value as CAN message for function monitoring and self-diagnosis (heartbeat)

Software update in the installed network, during runtime

Timeout control (RX) through monitoring received messages based on time

Voltage control through cyclic measurement of supply voltage, signal output if voltage drops below a minimum voltage and/or if the keypad is shut off

front side, in compliance with IP67

Design according to requirement profile

Layout and design options of miunske operating devices

Individual button assignment, illumination concepts, symbols and interface design for perfect and intuitive operation.

CAN control panels from miunske can be individually customized to meet specific requirements depending on the application area and use case. The configuration options range from selecting individual symbols to optional bargraph LEDs, as well as custom labeled layouts, such as application-specific functional layouts in the form of the vehicle. Additionally, customers can choose between the standard black frame color and decorative metal coating. There are also various mounting and connection options available to facilitate integration into the desired environment. Customers who need solutions beyond standard control panels, such as custom control concepts with separate displays, have the option to combine miunske operating devices with additional encoders.

All design options can be found in detail in the options brochure.

You can find out how to get to the individual CAN-BUS operating device 2G in the adjacent video tutorial.

To assist customers with the configuration, miunske provides a form that facilitates the communication process and the selection of individual options.

The configuration form can be found in the download area.

Smart functionality

Parameterization and integration of the vehicle operating devices with the miunske-toolchain

How do customers get their customized operating panel on the software side?

CAN control panels can be easily configured and parameterized by customers using the miunske-toolchain software package.

This software is available for free download on the miunske website.

In combination with a CAN sample kit, which includes all hardware components needed for developing a custom CAN control, CAN control panels can be directly programmed via a PC.

With the available tools, customers can choose to configure their control units themselves or entrust the task to our skilled development and project team.

Since miunske’s CAN control units support CAN Bus protocols such as J1939, CIA447, FireCAN, and CANopen, they meet a wide range of control requirements in commercial vehicles and mobile working machines. Additionally, they can be easily integrated into existing vehicle architectures.

Extreme flexibility in the field of foil design

Design and finalize the foil of the operaing panel yourself

To give customers maximum flexibility in designing and finalizing their control devices, and allow quick adjustments to customer requests, it is not only possible to make software modifications using the miunske-toolchain, but also to finalize the manufacturing of the front foil themselves. Detailed information on this can be found in the flyer “Customizing Control Panels.”

Equipped for any vehicle environment

To meet technical requirements in real vehicle applications, miunske offers control devices with front-side IP67 protection. When installed outside the driver’s cab, customized solutions in an additional housing can be implemented to provide comprehensive protection against moisture ingress and mechanical impacts.

Control devices for innovative vehicles of all branches

miunske CAN Bus Control Devices 2G offer a well-designed solution for modern vehicle and machinery control systems. Thanks to their easy integration into existing systems and high adaptability, they impress in terms of efficiency and user-friendliness. Whether in commercial vehicles, special machinery, or custom control solutions – miunske demonstrates that intelligent control devices bring not only functionality but also future-proofing. Those who rely on secure and flexible CAN bus technology will find a strong partner in miunske.

Practical application- integration examples

Specific application scenarios for the Can Bus operating device 2G

CAN-CONTROL DEVICES FOR RESCUE OPERATIONS

high-contrast, flexible operation and easy to clean

CAN-BUS OPERATING DEVICES IN COMBINATION

standard components in customized design

Would you like to find out more about miunske and our range of services?

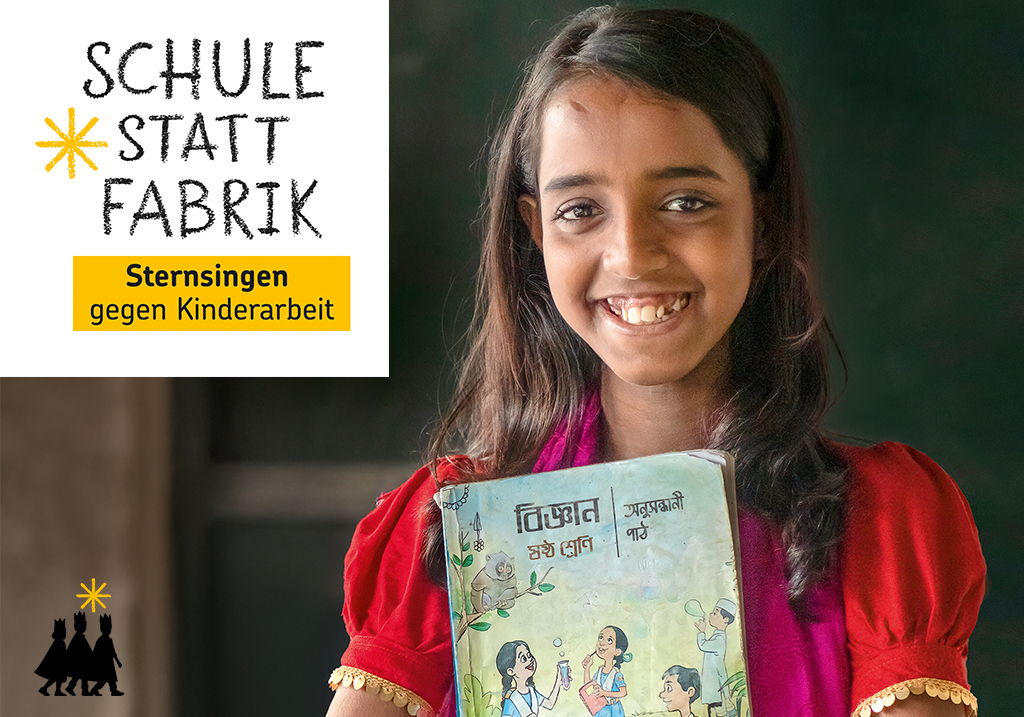

Carol singers 2026 at miunske

It is a wonderful tradition. The carol singers visit miunske® and bless the company buildings for this year. For miunske®, the visit is a meaningful

Upgrade your vehicle equipment—miunske offers TOP MTA S.p.A. antennas

High-quality vehicle antennas assist in vehicle networking To remain competitive in the market, manufacturers of commercial vehicles used globally have to develop stable network structures

TOPCON OPUS series for commercial vehicles

The perfect interface between vehicle technology and precise control tasks The integration of intelligent control units is a key task in modern vehicle development. The