Robust connections for commercial vehicle electronics press-fit technology & solutions by miunske

miunske makes electronics safe, powerful, and durable

miunske® focuses on the requirements for innovative electronic components and tailors its product portfolio and PCB assembly to the requirements of the commercial vehicle sector. With reliable and robust press-fit components as well as efficient and forward-looking connection technologies in press-fit technology, miunske meets the requirements for high currents, strong vibrations, and extreme environmental conditions in use. This article answers questions about the press-fit process, highlights its advantages, and provides an overview of the range of products offered by miunske GmbH, from press-fit components to printed circuit board manufacturing using press-fit technology.

What is press-fit technology?

high-level mechanical connections

miunske manufactures robust electrical assemblies and printed circuit boards using press-fit technology in its in-house production facility. In addition to THT and SMT assembly, the press-fit process is one of the most reliable methods of PCB assembly. miunske prefers to use press-fit components from its own production. Using suitable press-fit machines and the appropriate tools, the press-fit components are mechanically applied to the printed circuit board by pressing the specially shaped press-fit pins into the corresponding metallized holes in the printed circuit board.

In detail, the press-fit process works as follows:

- the press-fit pin is elastically deformable

- when pressed into the PCB hole, a gas-tight connection and thus a low-resistance electrical contact is created

- the press-fit connection is reflow and solder-free

Advantages of press-fit technology

Even more robust and individually manufactured electronic components

High reliability

- through gas-tight, vibration-resistant contacting

- low contact resistances

- high resistance to thermal and mechanical stress

Avoiding thermal stress

- no soldering errors, no cold solder joints

- protection of temperature-sensitive components

- minimal risk of failure

process advantages

- compact positioning of components and double-sided assembly of the circuit board are possible

- avoiding testing and reworking steps

- process flows completely in miunske’s control thanks to in-house production

- continuous optimization and process monitoring ensure high quality of the end product.

sustainability

- sustainable thanks to the elimination of solder and flux

High Quality

- assembly inspection by AOI

- stress tests in the in-house high-current laboratory

- functional testing based on set parameters and requirement profiles

Press-Fit components from miunske

Developed for demanding applications

miunske® has many years of experience in press-fit technology and processes its own Press-fit components such as:

Flat plug socket 6.3 & 9.5 mm

JPT connector 2 rows: 2×5, 2×9

JPT connector 3 rows A-coded: 3×2, 3×3, 3×4, 3×5, 3×6, 3×7 (black, brown, blue, yellow, grey, green, purple)

JPT contacts in silver-plated version possible

Relay socket micro & mini

MiniVal & UniVal fuse holder as well as obtained articles such as:

Power connections with internal thread: M5-M8

Power connections with external thread: M4-M10

Flat plug: 2.8 & 6.3 mm

Press-Fit service package from miunske

More than just components—genuine service and appropriate support

miunske® supports manufacturers of commercial and special-purpose vehicles as well as OEMs throughout the entire development and manufacturing process.

miunske® develops printed circuit boards and intelligent central electrical systems using press-fit technology for your application. Our experienced staff will accompany you from the initial idea to the finished assembly. In addition, customers are advised on possible design options, electrical parameters, and connection variants. Your project will be implemented in miunske’s own production facility as a professional press-fit service. Your printed circuit board is manufactured using suitable components, appropriate documentation, and thorough quality testing. Upon request, the project team will assist you with the implementation in your vehicle concept.

The following product brochure provides information on assembly technologies and the manufacture of customer-specific intelligent central electrical systems:

miunske TECH TALK Press-fit technology

miunske® provides customers with an insight into the manufacturing processes. Take a look at the video to learn more about the advantages of press-fit technology from the miunske team.

Don’t forget to follow the miunske group’s YouTube channel to stay up to date on the latest developments in PCB assembly at miunske.

Would you like to learn more about miunske and our range of services?

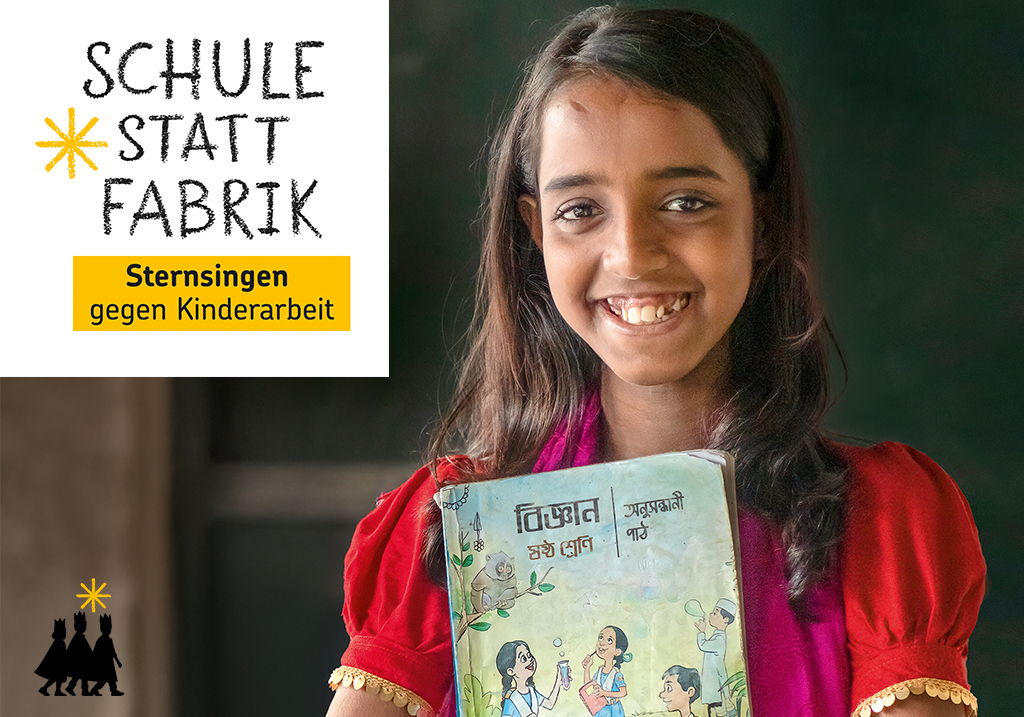

Carol singers 2026 at miunske

It is a wonderful tradition. The carol singers visit miunske® and bless the company buildings for this year. For miunske®, the visit is a meaningful

Upgrade your vehicle equipment—miunske offers TOP MTA S.p.A. antennas

High-quality vehicle antennas assist in vehicle networking To remain competitive in the market, manufacturers of commercial vehicles used globally have to develop stable network structures

TOPCON OPUS series for commercial vehicles

The perfect interface between vehicle technology and precise control tasks The integration of intelligent control units is a key task in modern vehicle development. The